Driers and Heat Exchangers

Driers and Heat Exchangers Brochure

Drier

Reduces zinc splashes

Reduces zinc ash and galvanizing fumes

Reduces the risk of deformation of thin materials

Increases the process speed by faster dipping

- Heat resistant chain conveyor system

- Covers, strenghtened with profiles

- Ducts for blowing air

- Insulation: Rock wool

- Paint: Sand blasting, 1 layer of primer, 2 layers of epoxy paint, 120 microns

- Plenums

- High capacity circulation fan, with invertor and valves etc.

- Burner system, with valves etc.

- PLC controlled panel

- Thermocouple

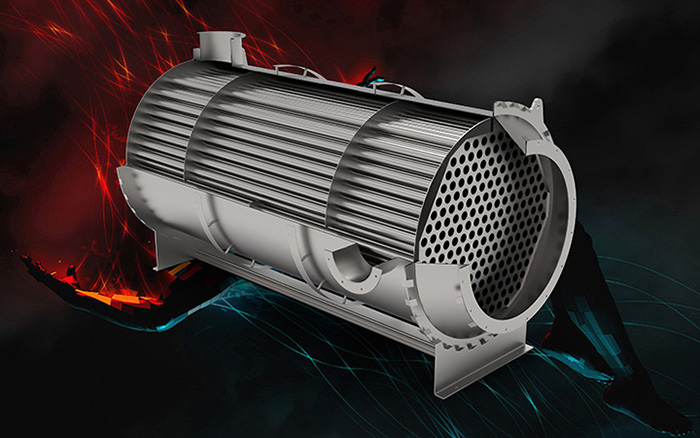

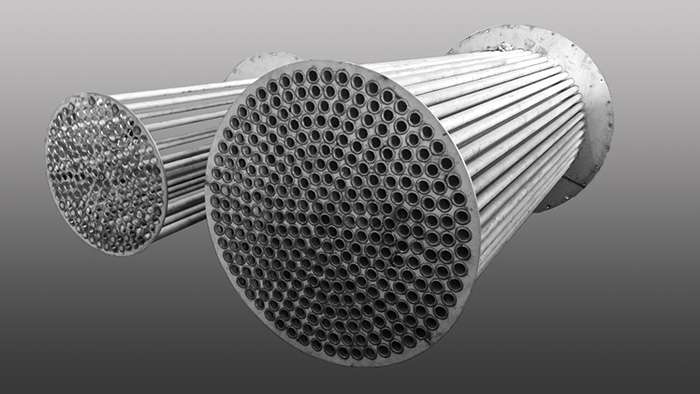

Heat Exchanger for the Drier

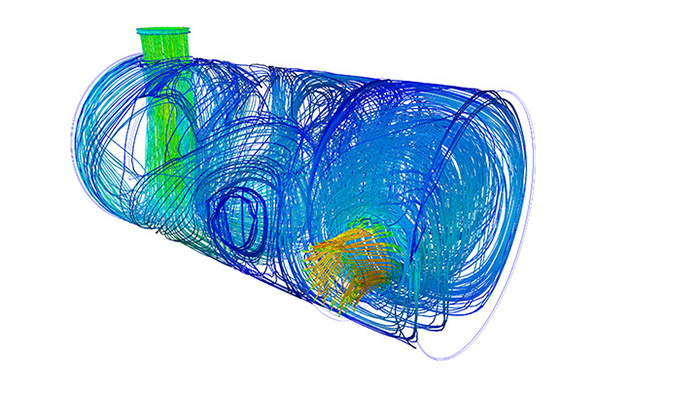

Uses the excess energy of the galvanizing furnace to heat the drier. Hot air from the furnace passes inside of the stainless steel pipes and heates the air outside of the pipes, reducing the energy need of the drier.