Table of Contents

Nickel Tablet Saves Money

In today’s fast-evolving industrial sector, cost optimization is essential. Galvanizers are constantly seeking innovative methods to reduce expenses while maintaining high-quality standards. A standout solution that’s gaining widespread recognition is the use of nickel tablets—a simple, yet highly effective product that significantly reduces costs and enhances operational efficiency.

How Nickel Tablets Transform the Galvanizing Process

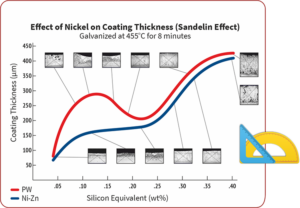

Nickel plays a vital role in controlling coating thickness during the galvanizing process. It’s the only element capable of preventing excessive zinc-iron alloy formation, which can lead to thick coatings, peeling, and matte gray finishes. This is especially beneficial when working with silicon-containing steels (commonly known as Sandelin steels) that have a silicon content of 0.04-0.15%. Nickel ensures optimal coating thickness, reduces defects, and improves overall appearance.

For silicon-containing steels, zinc coatings can range from 140 to 200 microns and, in some cases, exceed 300 microns. Nickel is the only element that effectively limits these excessive thicknesses, reducing zinc consumption by an impressive 10-15%. This translates to significant cost savings over time.

Improving Efficiency and Quality

Improving Efficiency and Quality

Nickel tablets dissolve evenly and efficiently in molten zinc, ensuring a consistent alloy composition throughout the process. This not only accelerates production but also improves the quality and consistency of the final coating. The result is a smoother, more durable finish.

A Smarter Investment for Superior Coating

At Anı Metal, we’ve applied our extensive expertise to develop the SmartNi nickel tablets—a solution designed to meet the unique needs of galvanizers worldwide. Our premium product contains 100g of pure nickel and 35g of melting agents, offering several key benefits:

At Anı Metal, we’ve applied our extensive expertise to develop the SmartNi nickel tablets—a solution designed to meet the unique needs of galvanizers worldwide. Our premium product contains 100g of pure nickel and 35g of melting agents, offering several key benefits:

- ANI Metal SmartNi create more heat shield

when burn off therefore they prevent consumption by oxidation.

when burn off therefore they prevent consumption by oxidation. - Increases the solubility in zinc.

- Prevents the precipitation to dross.

Additionally, the SmartNi nickel tablets are designed with a lighter overall weight—just 135g per tablet—making them easier to handle and providing galvanizers with better control during the process. This compact design allows for precise and effortless concentration adjustments, ensuring optimal results with minimal effort.

By using SmartNi nickel tablets, galvanizers can reduce nickel usage by up to 30% compared to traditional zinc-nickel alloy ingots or nickel powder applications. Here’s a comparison of nickel consumption for different alternatives:

Zinc-Nickel Alloy Ingots: 1.7 kg of nickel per ton of zinc

Nickel Powder: 1.8 kg of nickel per ton of zinc

Nickel Tablets (SmartNi): 1.2 kg of nickel per ton of zinc

For more details on use of SmartNi, kindly visit our SmartNi page.

For more details on use of SmartNi, kindly visit our SmartNi page.

Improving Efficiency and Quality

Improving Efficiency and Quality when burn off therefore they prevent consumption by oxidation.

when burn off therefore they prevent consumption by oxidation.