Automatic Crane Systems

since

Automatic Crane Systems Brochure

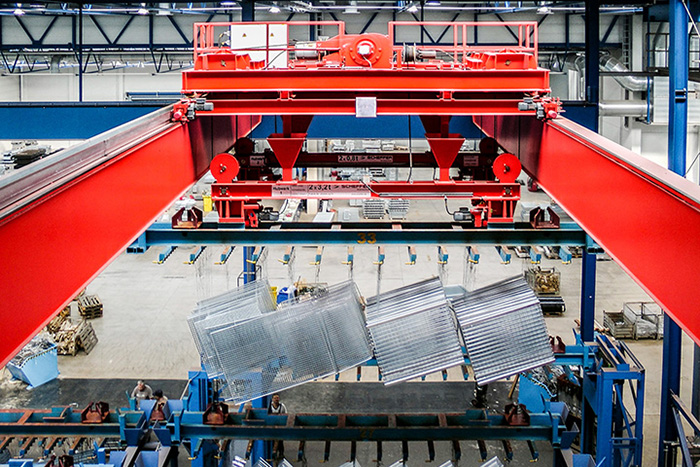

- Automatic and semi-automatic galvanizing plants

- State-of-the-art technology transportation systems

- Tailor made solutions

- High efficiency

- Computerized process control and monitoring

- Reliability

- Durability

Understanding Automatic Crane Systems

Automatic crane systems have emerged as integral components of modern industries, providing advanced lifting solutions for a wide range of applications. These systems are powered by automation technologies, allowing for precise and efficient movement of heavy materials without the need for constant human intervention. The evolution of automatic cranes has significantly enhanced productivity and safety in industrial settings, making them indispensable in sectors such as manufacturing, construction, and logistics.

The Role of Automation in Modern Industries

Automation has revolutionized industries across the globe, and the crane system is no exception. With the ability to operate autonomously, automatic cranes have reduced the need for manual labor while improving operational efficiency. From controlling load movements to integrating with advanced systems like IoT and artificial intelligence, automated cranes are shaping the future of material handling and transportation.

Table of Contents

Types of Automatic Crane Systems

Bridge Cranes: Precision in Horizontal Movements

Functionality and Applications

Bridge cranes, often referred to as overhead cranes, are designed to move heavy loads along horizontal tracks suspended from two parallel beams. The crane itself moves along these tracks, allowing it to cover a large area within a facility. This type of crane is commonly used in manufacturing plants, warehouses, and steel mills for lifting heavy loads across long distances.

Advantages in Industry

The automatic bridge crane excels in its precision and versatility. It can carry massive loads with exceptional control, minimizing the risk of accidents and inefficiencies. Automated bridge cranes can also operate in tight spaces, reducing the need for large-scale, traditional lifting equipment. The incorporation of sensors and control systems ensures that these cranes move with pinpoint accuracy, providing optimal performance in various industrial sectors.

Jib Cranes: Flexibility and Control

How Jib Cranes Operate

Jib cranes are characterized by a horizontal arm (the jib) that extends from a central vertical column. These cranes are particularly suited for smaller spaces where flexibility and control are necessary. Automatic jib cranes offer the ability to rotate and extend their reach, allowing for precise handling of loads within confined areas such as workshops and assembly lines.

Benefits for Smaller Operations

For smaller operations that do not require the extensive reach of a bridge or gantry crane, the jib crane offers an ideal solution. Its compact design allows it to fit into tight spaces, while automation ensures that operations remain seamless and consistent. With fewer human operators required, jib cranes help reduce labor costs while enhancing safety and productivity.

Gantry Cranes: Heavy Duty with Mobility

Key Features of Gantry Cranes

Gantry cranes are heavy-duty lifting systems mounted on wheeled tracks, allowing them to be used in outdoor environments or on large-scale construction projects. These cranes consist of a bridge supported by two legs, making them incredibly versatile and mobile. Automated gantry cranes can be programmed to move materials along both horizontal and vertical axes, making them ideal for a variety of heavy lifting tasks.

Industries that Rely on Gantry Cranes

The construction, shipbuilding, and transportation industries heavily rely on gantry cranes for their ability to handle large loads with mobility. In ports, gantry cranes are used to load and unload containers, while in construction, they assist with lifting and moving heavy equipment and materials across vast sites. Their robust structure and ability to navigate large areas make them invaluable assets to many industrial applications.

Advantages of Automatic Crane Systems

Increased Efficiency and Productivity

Automatic crane systems significantly improve efficiency by reducing downtime and optimizing the handling of materials. The precision offered by these systems ensures that loads are moved quickly and safely, reducing cycle times and increasing throughput. As automation minimizes human error, tasks that once took considerable time are now completed faster, ultimately enhancing overall productivity.

Enhanced Safety and Reduced Labor Costs

Safety is one of the key advantages of automatic crane systems. With automation in place, the risk of accidents due to human error is minimized. Automated systems are equipped with sensors and safety protocols that prevent overloading, ensure proper load positioning, and stop the crane if any malfunction occurs. Moreover, automation reduces the need for human labor, cutting costs associated with staffing while improving workplace safety.

Precision and Reliability in Operations

Automatic cranes are known for their reliability and precision. With programmed movements and automated controls, these cranes consistently achieve accurate load positioning and handling. The reduction in human involvement also reduces the chances of operational delays caused by fatigue or error. The ability to repeat tasks with the same level of accuracy ensures that operations run smoothly and with minimal disruptions.

Technological Innovations in Automatic Crane Systems

Integration with IoT and Smart Technologies

Modern automatic cranes are increasingly integrating with IoT (Internet of Things) technologies. This integration enables cranes to be connected to a central system, where data is collected in real-time. Operators can monitor performance, predict maintenance needs, and improve the efficiency of the lifting operations. With smart sensors and data analytics, these systems are evolving to be even more autonomous and self-optimizing.

Future Trends and Developments

The future of automatic crane systems lies in further advancements in AI, machine learning, and robotics. These technologies will enable cranes to perform even more complex tasks, such as handling a wider range of materials, navigating more intricate spaces, and interacting with other machines in real-time. Additionally, advancements in energy-efficient designs and environmental sustainability will make these cranes even more cost-effective and eco-friendly in the coming years.

The Future of Crane Automation in Industrial Operations

Automatic crane systems are transforming material handling and lifting operations across multiple industries. With increased efficiency, precision, and safety, these systems represent the future of industrial lifting. As technological advancements continue to push the boundaries of automation, the capabilities of cranes will expand, offering even more innovative solutions for modern industrial operations.

Automatic Crane Systems – Hot Dip Galvanizing | ANI METAL

Automatic Crane Systems – Hot Dip Galvanizing | ANI METAL